Präsentationen Stakeholder Workshop “Innovative Bastfaseranwendungen für die Industrie”

- Vorstellung des DuroBast Projektes Fraunhofer Institut LBF (Dr. Roland Klein, Projektleiter)

- Forschung und Entwicklung mit Naturfasern in Deutschland – Fachagentur Nachwachsende Rohstoffe (Robert Hardt)

- Innovative Faserhydrophobierungsverfahren für Naturfasern – Fraunhofer Institut LBF (Lais Weber)

- Feine Hybridgarne aus non-woven Naturfasern und deren Verarbeitung zu Textilen-Flächen – Institut für Textiltechnik (ITA) der RWTH Aachen (Leonie Wesener und Amanda Kulessa)

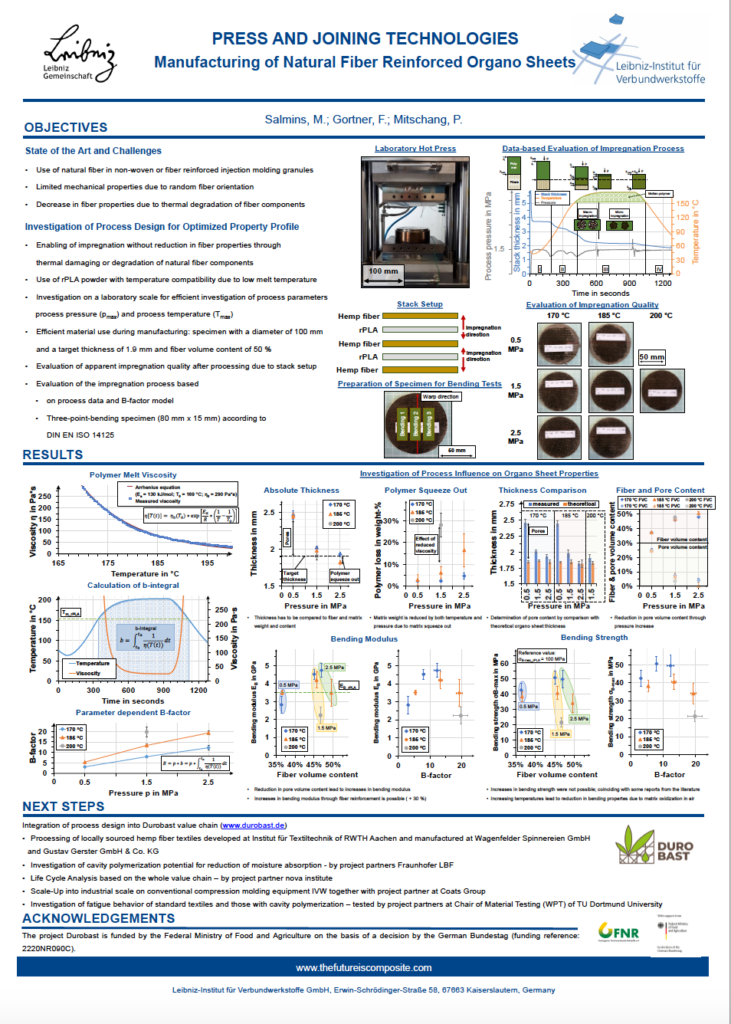

- Herstellung von Organoblechen mit Recycling-PLA – Leibniz Institut für Verbundwerkstoffe (IVW) (Maximilian Salmins)

- Neue Erkenntnisse zum Versagensverhalten Naturfaserverstärkter Kunststoffe mit Maßgeschneiderten Testmethoden – Lehrstuhl für Werkstoffprüftechnik (WPT) der Technischen Universität Dortmund (Ramon Helwing)

- Techno-Ökonomische Betrachtung von Naturfaseranwendungen – nova-Institut (Olaf Porc)

- Naturfaser-Endanwendungen im Bereich Snow-Boards und Sport-Equipment – Silbaerg (Dr. Jörg Kaufmann)

Multiple amplitude testing method for detection of local damage evolution in bast fiber-reinforced polymers

Ramon Helwing, DUGi Media Publication

Cycle-consistent generative adversarial networks for damage evolution analysis in fiber-reinforced polymers based on synthetic damage states

Ramon Helwing, Selim Mrzljak, Daniel Hülsbusch, Frank Walther, in Composites Science and Technology

Volume 254, 26 July 2024, 110695

Erhöhung der Nachhaltigkeit von gewebeverstärkten Organoblechen

M. Salmins, P. Mitschang

Gewebe aus Hybridgarnen für eine vereinfachte Herstellung von naturfaserverstärkten Organoblechen

M. Salmins, T. Neumeyer

DuroBast: Harnessing Durability and Resource Efficiency through Advanced Bast Fiber Treatment

Dr. Roland Klein, Conference Proceedings, Cellulose Fibres Conference 2024, 19-20 March 2024, Cologne, Germany.

Heimische Bastfasern für Busse, Boards und Automobilausstattung

M. Salmins, P. Mitschang

Ermittlung geeigneter Prozessparameter für die Herstellung von Flachsfaserverstärkten Organoblechen

M. Salmins, P. Mitschang

Investigation of the mechanical performance of hydrophobised hemp fibres in combination with polypropylene using pull-out tests

Wesener, L.; Salzwedel, L.; Weber, L.; Proceedings SAMPE Europe Conference & Exhibition 2023 : El Escorial Madrid, Spain, 3 – 5 October 2023. – Oranjewoud, Netherlands: SAMPE Europe Administration, 2023

Challenges in Manufacturing of Hemp Fiber-Reinforced Organo Sheets with a Recycled PLA Matrix

Maximilian Salmins; Florian Gortner; Peter Mitschang: published in Polymers Vol. 15, Issue 22, 2023; DOI: https://doi.org/10.3390/polym15224357

Poster: Press and Joining Technologies – Challenges in Manufacturing of Hemp Fiber-Reinforced Organo Sheets with a Recycled PLA Matrix

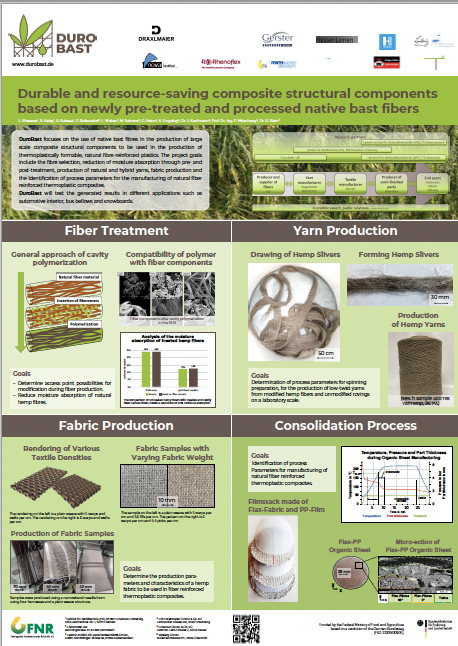

Durable and resource-saving composite structural components based on newly pre-treated and processed native bast fibres